Products & EquipmentResearch, Development, and Quality Control

Research and Development

The Advanced Surface Treatment Technologies That Support Industrial Development

There is remarkable diversity to the various usage cases for surface treatment technologies: creating beautiful surface finishes, preventing rusting, hardening materials, reducing surface friction, coloring surfaces, creating matte finishes, and much more.

We work with integrity to meet needs like these from the market, using the experience and know-how we have accumulated over the years. At TAKAMATSU PLATING, we offer outstanding electroplating that adds various functions to a wide variety of materials.

A Closer Look at a Technology We Have Developed

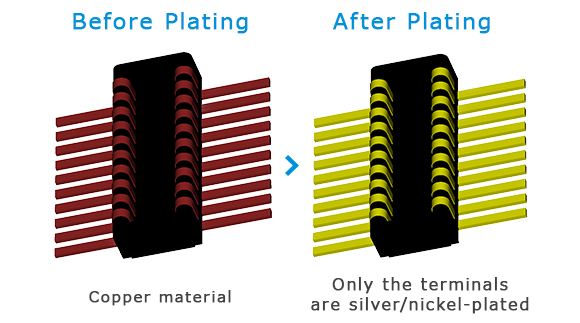

Reel-to-Reel Plating after Assembly

Cut down on plating work time!

Cut down on plated pins that get thrown away, through full-item processing!

Reduce solder soaking into the resin!

Reduce costs and improve turnaround time!

Trustworthy technology used for many products!

We offer reel-to-reel plating for products that have been pressed and attached to resin parts. (Patented process.)

We can also plate just a single pair of terminals that are insulated with molded resin, which can lead to reductions in plating work time.

This also cuts down on plated pins that get thrown away.

Only the portions that are not in contact with the molded resin are plated, which helps to prevent solder from soaking into the resin. (Portions in contact with resin are not plated.)

Quality Control

A Strict Management System to Ensure High Quality

The parts used in precision electronic equipment have high standards for precision and quality. In order to meet the needs of customers focused on these highly sophisticated items, TAKAMATSU PLATING uses cutting-edge measurement and testing equipment as part of our strict quality management system.

In 2001, we acquired ISO 9001 certification, making our thorough quality management structure even more systematic and advanced than ever before.

Measuring and Testing Equipment

| Type of Equipment | |

|---|---|

| Solder tank | |

| Hot plate | |

| X-Ray Coating Thickness Measurement | |

| EDS | |

| ICP PS3510DDII (Hitachi High-Tech Science) | |

| Nano Indenter HM-500 (Fischer) | |

| Laser Scanning Microscope VK-8700 (Keyence) | |

| Solder Checker SAT-5100/5200 (Rhesca) | |

| Micro Hardness Tester HMV-G21DT (Shimadzu) | |

| Spectro-photometer UV-1240mini (Shimadzu) | |

| Liquid Chromatograph 1220 InfinityII LC System (Agilent Infinity) | |

| Electric Contact Simulator CRS-1 (Yamasaki Seiki) | |

| Highly Accelerated Stress Tester EHS-211 (Espec) | |

| Salt Spray Tester S120s (Ascott) | |

| Bench-Top Type Temperature and Humidity Chamber SH-241 (Espec) | |

| Thermostatic Chamber | |

| Reflow Checker RDT-250C (Malcom) | |

| Microscope(CCD Camera) VHX Series (Keyence) | |

| Autograph AGS-J50N (Shimadzu) | |

| X-Ray Fluorescence Spectrometer EDX-7000 (Shimadzu) | |

| FT-IR AIM-8400S (Shimadzu) | |

| Image Dimension Measurement IM-6020 (Keyence) | |

| Micro Colormeter VSR-400 (Nippon Denshoku) |

Scanning Electron Microscope

X-Ray Fluorescence Thickness Measuring Instrument

Copyright TAKAMATSU PLATING Co.,Ltd. All Rights Reserved.